Insert Fittings into Plastic & Rubber Tubing with Precision — A Practical Guide

In modern manufacturing and laboratory environments, understanding how to insert fittings into rubber tubing and plastic tubing is essential for seamless assembly and reliable performance. Whether you’re handling flexible tubing in biomedical setups, cleanrooms, or industrial systems, mastering the right techniques—and using the appropriate tools—can eliminate error and boost productivity. This guide explores key steps to follow and shows how Clean Room Devices’ specialized fitting inserters streamline the process.

Why Technique Matters in Tubing Assembly

Rubber tubing offers flexibility and resilience, but that same flexibility can make fitting insertion tricky. Too much manual force may distort the tubing, cause misalignment, or lead to leaks and future failure. Conversely, too little force can result in improper seating, which compromises connection integrity.

Beyond seal reliability, ergonomics plays a role: repetitive, force-intensive fitting insertion can strain technicians—especially when handling high volumes.

Traditional Methods vs. Advanced Tools

Traditional approaches to inserting fittings into rubber or plastic tubing—like manual force or heating the tubing—can be inconsistent, inefficient, and physically demanding. These methods may work for low-volume setups but often fall short in cleanroom environments where precision, repeatability, and contamination control are critical.

Clean Room Devices offers a better solution with their line of cleanroom-compatible fitting inserters. Designed to reduce operator strain and improve connection accuracy, these tools—ranging from manual models like the CRD410 to automated systems like the CRD600—streamline the way technicians insert fittings, especially in high-volume, regulated production environments.

Step-by-Step: How to Insert Fittings into Rubber Tubing

- Check Tubing & Fitting Compatibility

Confirm the outer diameter of the tubing fits the fitting geometry precisely—too tight, and insertion is hard; too loose, and sealing suffers. - Optional Preconditioning

Some operators gently warm the tubing end to aid insertion, especially with rigid plastics. But always consider safety and material limits. - Insert with Control

Using either manual force or a tool, insert the fitting until fully seated—ensuring a secure, leak-resistant connection.

Cleaner & Safer: How Clean Room Devices Enhances Fitting Insertion

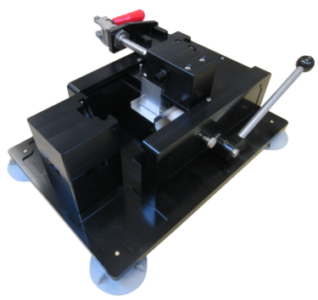

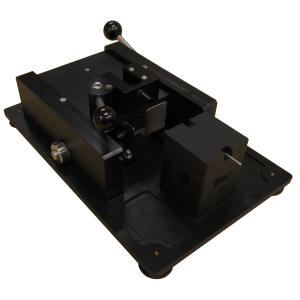

We provide an effective alternative to traditional methods when it’s time to insert fittings into plastic or rubber tubing. Our Manual Fitting Inserters (CRD410, CRD430) use ergonomic lever action tailored for cleanroom-compatible assembly—no power or external air needed:

- CRD410: Accommodates tubes from 1/16″ to 1/2″ O.D., offers rotating nests for multi‑barb fittings, and reduces force and repetitive strain.

- CRD430: Suited for larger or heavy-duty tubing (up to 1‑5/8″ O.D.), also cleanroom-compatible and ergonomic Clean Room Devices.

For higher-volume or complex geometries, the CRD400 Fitting Inserter delivers semi‑automatic precision with rotating nests that handle Y, T, and union fittings. Widely used for cleanroom medical tubing assembly, it supports complex shapes and aligns with accuracy.

Automation peaks with the CRD600, a pneumatic inserter offering smart relay control, high throughput (400–800 insertions per hour, or up to 1,800 with a bowl feeder), and minimal manual effort. It improves repetitive control and reduces hand strain—key benefits when inserting fittings repeatedly.

Our inserters uphold cleanroom standards, ensuring low particle generation and featuring smooth surfaces for easy cleaning—ideal for GMP, sterile manufacturing, and controlled environments.

Benefits for Your Process

- Consistency: Inserters deliver precise, repeatable fitting depth and alignment.

- Ergonomic Advantage: Leveraged or powered insertion drastically reduces force and fatigue.

- Flow Efficiency: Higher throughput and less manual handling speed up production.

- Cleanroom Fit: Engineered for contamination control, with smooth, tool-friendly materials and minimal particulation.

News & Industry Context

Recent advancements emphasize transitioning from solvent bonding (common with PVC) to mechanical fitting insertion, particularly for elastomeric tubing. A notable example in medical manufacturing showed that using the CRD600 for TPE Medalist® tubing achieved stronger retention strengths than solvent bonding—without chemical exposure or odors, and at high assembly speeds of over 1,800 insertions per hour.

Elevating Your Tubing Assembly Process

To insert fittings into rubber tubing effectively, combining right-fit technique and ergonomic tooling is key. Traditional methods provide a baseline, but modern production demands consistency, safety, and cleanroom compatibility. At Clean Room Devices’, our range—from manual to automatic inserters—offers scalable solutions for precise, fatigue-free assembly.

Want help selecting the optimal inserter model? I can help you outline the right fit for your tubing size, volume, and operating environment!