Choosing the Right Tubing Expander Tool: Time‑Delay & Sensor Technologies Explained

In high‑precision assemblies, a reliable tubing expander tool is key to preparing flexible plastic or rubber tubing for secure fitting installation. Whether you’re working in cleanrooms or on medical‑grade tubing systems, the right tool affects ergonomic performance, repeatability, and product quality. This article explains how modern tubing expander tools with time‑delay and sensor features benefit operators and processes, and highlights how Clean Room Devices offers practical solutions for these needs.

Why a Tubing Expander Tool Matters

Without pre‑expansion, inserting barbed fittings into tubing often requires excessive force—especially with stiffer materials. A tubing expander tool opens the tubing end uniformly, enabling the fitting to slide on more easily, reducing operator fatigue and minimizing the chance of damage. On the Clean Room Devices website, they are described as devices that “allow barbed fittings to be installed in stiffer tubing… expanding tube prior to fitting installation helps prevent operator fatigue and mitigates injury.”

When you select a tubing expander tool designed for cleanroom use, you’re not just improving performance—you’re reducing risk of repetitive strain injury (RSI) caused by repeated hand‑force and awkward motion. In cleanroom environments, where production may be high‑volume, this is an important ergonomic improvement.

Time‑Delay and Sensor Features: What They Do

Modern tubing expander tools often include two key enhancements: time‑delay relays and sensors. These features help ensure repeatability, safety, and ergonomic benefit.

- Time‑delay relay: Allows you to set how long the jaws remain opened or expanded, and possibly how long between cycles. For example, the CRD201 time‑delay model from Clean Room Devices uses this control so that each expansion occurs at a consistent rate rather than relying on manual timing.

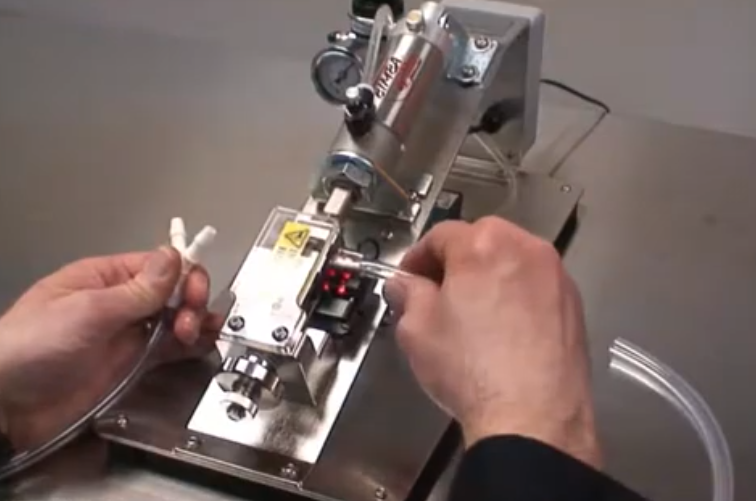

- Sensor actuation: Some models detect the presence of tubing and automatically trigger expansion, which reduces manual triggers and ensures timely workflow. The CRD202 model highlights this: “the unit is designed to use a photo‑sensor that will automatically sense the presence of tubing over the jaws.”

These features provide three main benefits:

- Consistent expansion – Every piece of tubing is expanded for the same duration and force, reducing variability.

- Reduced operator fatigue – Hands are freed from repetitive triggers or awkward holds; foot pedals or sensors automate the motion.

- Cleanroom compliance – As expanders from Clean Room Devices are built with stainless steel and low‑particulate construction, they integrate cleanly into controlled manufacturing environments.

Specific Expanders to Consider

Here are a few tubing expander tools from Clean Room Devices that illustrate how the technology works and supports ergonomic assembly:

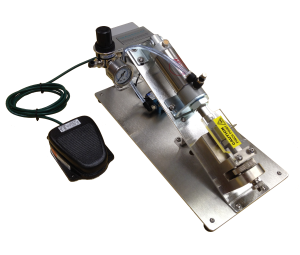

- CRD200 Expander – A basic model with stainless steel base and pedal actuation; helps reduce operator strain by simplifying the expansion step ahead of insertion.

- CRD201 Time‑Delay Expander – Adds a time‑delay relay so each expansion cycle is consistent; ideal when multiple operators or frequent changeovers require repeatability.

- CRD202 Time‑Delay Expander with Sensor – Employs both sensor detection and dual time‑delay settings (expansion time and interval time) for automated, hands‑free workflow in demanding environments.

Each tool is optimized for cleanroom use in medical device manufacturing, enabling ergonomic steps without sacrificing control or cleanliness.

Integrating into Your Process

To get the most from a tubing expander tool, consider these best practices:

- Identify tubing materials (rubber vs. plastic) and diameters. Stiffer tubing often needs time‑delay control to prevent splitting.

- Train operators on the difference: manually expanding vs. using the tool. Highlight how less manual force helps prevent repetitive strain injury.

- Monitor cycle times and finished parts: Compare before & after tool implementation for throughput and quality.

- Ensure cleanroom standards: Use tools rated for ISO 7/8 environments so chose models with stainless steel bases and minimal particle generation.

- Incorporate into ergonomic assessments: A good tool reduces wrist torque, repetitive motion, and awkward postures—core aspects of ergonomics in manufacturing industries.

Elevating Your Operation with the Right Tool

In modern high‑precision manufacturing, a tubing expander tool isn’t just a convenience—it’s a strategic investment in efficiency, quality, and worker well‑being. By choosing a tool such as the CRD201 or CRD202 with time‑delay and sensor capabilities, manufacturers in medical device manufacturing can reduce the risk of repetitive strain injury, boost consistency, and sustain high throughput without sacrificing cleanroom compliance.

If you’re ready to improve your expansion process, request a consultation with Clean Room Devices to match your tubing materials, diameter, and production demands with the right expander model.