Cleanroom Accessories That Boost Productivity: What’s Worth Adding?

In cleanroom environments, precision and consistency are non-negotiable. Every step of the process—from cutting and expanding tubing to inserting fittings—must be repeatable, efficient, and compliant with strict particulate and ergonomic standards. While primary tools like inserters, expanders, and cutters often get the spotlight, it’s the cleanroom accessories behind the scenes that keep workflows smooth and operators productive.

These add-ons may seem minor at first glance, but in ISO-certified environments where repeatability and efficiency drive both quality and compliance, accessories can significantly impact daily performance.

The Value of the Right Cleanroom Accessories

Choosing the right cleanroom accessories isn’t just about convenience—it’s about process control. Whether it’s a cutter shelf that improves tool stability, a rotating nest that reduces wrist strain, or a replacement blade that ensures precise cuts, these accessories help reduce rework, operator fatigue, and alignment errors.

Accessories provide:

- Ergonomic support that reduces repetitive strain

- Greater repeatability for high-throughput operations

- Fewer misalignments during multi-step processes

- Reduced operator downtime for cleaning, adjustments, or tool transitions

These benefits are especially valuable when working in cleanrooms that must comply with ISO 7 or ISO 8 standards, where even small variations in operation can result in contamination or performance failures.

Cleanroom Accessories in Action: Examples from Clean Room Devices

Here are several standout accessories available from Clean Room Devices that demonstrate how thoughtful design can streamline processes and protect both products and people:

Replacement Blades

Available for CRD’s manual and semi-automatic tubing cutters, these accessories are critical for maintaining cutting consistency. Worn blades can create jagged edges or tubing deformation, which can impact downstream assembly. Quick-change blade holders allow for safe, efficient maintenance without compromising sterility.

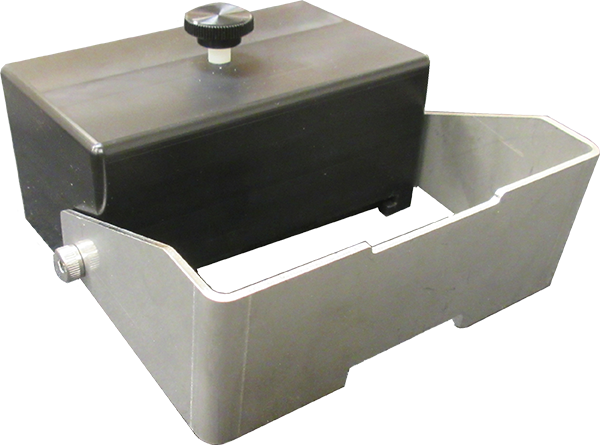

Jaws & Custom Nests

Clean Room Devices offers a variety of jaw configurations to accommodate different fitting geometries and tubing sizes. These custom nests help ensure proper alignment and repeatable insertion depth—critical for reducing operator error and improving assembly precision in high-throughput environments.

Foot Pedals & Time Delay Modules

Foot pedals, often paired with pneumatic or electro-pneumatic tools, allow for hands-free operation, maintaining cleanroom posture protocols and minimizing strain. Time delay accessories offer improved control over expansion or insertion cycles, especially useful in tools like the CRD201 tubing expander.

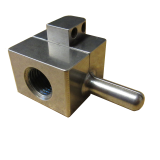

Slide Blocks

Slide blocks are essential for guiding tubing into the correct position during cutting or expansion. By maintaining consistent alignment and reducing unnecessary movement, slide blocks enhance accuracy and reduce operator handling—especially important in ISO-classified cleanroom environments.

Accessory vs. Upgrade: Which Is the Right Move?

When production needs evolve, manufacturers often face the decision of whether to purchase an entirely new tool or simply add an accessory. The right answer depends on your goals.

Choose an accessory when:

- You want to improve an existing process without major equipment changes

- Ergonomic or repeatability issues stem from setup, not the tool itself

- A cleanroom tool still meets volume requirements, but needs slight refinement

Consider a full tool upgrade when:

- Output demand exceeds current tool capabilities

- You’re transitioning to a different tubing size or material

- Manual operations are causing injury or errors despite accessories

In many cases, investing in targeted cleanroom accessories offers the best ROI, especially when budgets are tight but performance expectations are rising.

When Small Add-Ons Make a Big Difference

In high-stakes industries like medical device manufacturing, pharma, or biotech, the right accessory can mean the difference between a pass or fail during an audit—or a pass or fail on the production floor. While it’s easy to overlook small items like blade holders or foot pedals, they play a pivotal role in maintaining cleanliness, reducing manual strain, and ensuring compliance.

As tool design continues to evolve for cleanroom compatibility, Clean Room Devices remains at the forefront by not only offering high-quality inserters, expanders, and cutters, but also the supporting cleanroom accessories that keep cleanrooms running efficiently.

Building a Smarter Setup, One Accessory at a Time

Optimizing cleanroom productivity doesn’t always require big equipment changes. Sometimes, it’s the right accessory—a rotating nest, a mounting shelf, or a precise foot pedal—that quietly improves your entire process. With a full catalog of cleanroom accessories engineered to support sterility, repeatability, and ergonomics, Clean Room Devices helps you fine-tune your environment for lasting performance.