How Pass‑Through Windows Streamline Workflow in Pharmaceutical Cleanrooms

In pharmaceutical cleanrooms, every transfer of materials—be it supplies, documentation, samples, or waste—must avoid disrupting airflow, pressure, or sterility. Pass‑through windows (also called pass‑through chambers or boxes) are vital tools that help labs maintain controlled environments while optimizing material flow.

This post explores how pass‑through windows work in pharmaceutical cleanrooms, detailing their functions, hygiene benefits, regulatory compliance advantages, and relevant industry updates.

What Pass‑Through Windows Do

Pass‑through windows are interlocked transfer chambers installed in walls between cleanrooms and adjacent areas like packaging, staging, waste zones, or gowning areas. Their primary purpose is to:

- Facilitate the transfer of materials without requiring personnel to enter or exit the cleanroom.

- Maintain critical air pressure differentials and avoid contamination during transfers.

- Reduce gowning/de-gowning cycles, saving time and minimizing particulate intrusion.

These benefits are especially important in pharmaceutical cleanrooms, where GMP and ISO 14644 standards require stable environmental conditions and minimal cross-contamination.

Design Features Tailored for Pharmaceutical Use

To meet the strict needs of pharmaceutical cleanrooms, pass‑through windows in these settings often include:

- Mechanical interlocks: Prevent both doors from opening simultaneously, preserving pressure differentials.

- HEPA-filtered options: Some active models purge and re-filter the interior air before transfer, ensuring particulate-free passage.

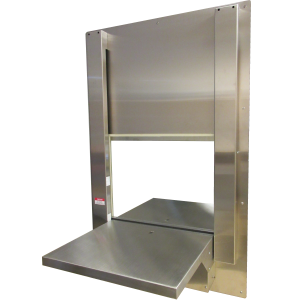

- Durable, hygienic materials: Units are typically built from 304 or 316L stainless steel, with coved interiors to prevent particle buildup and ensure easy cleaning.

- Compact design: Ideal for cell and gene therapy setups where space is tight, preserving cleanroom footprint compared to large airlocks.

Clean Room Devices offers both manual and fully automated pass‑through windows that install in minutes and integrate seamlessly into modular cleanroom walls.

Measurable Benefits in Real‑World Operations

Pass-through windows offer a range of measurable benefits for pharmaceutical cleanrooms. First and foremost, they significantly reduce the risk of contamination by minimizing unnecessary personnel movement, which is crucial in environments where even the smallest particulate or microbial breach can compromise product quality. These windows also improve workflow efficiency by eliminating repeated gowning and de-gowning cycles, leading to savings in both time and gowning supplies. In addition, by acting as sealed airlocks, pass-through windows help maintain the stable pressure differentials essential for cleanroom integrity. Compared to larger material airlocks, they also offer a compact footprint, making them especially valuable in cleanroom environments where space is limited—such as in cell and gene therapy suites.

Industry & Regulatory Context

Recent trends in cell and gene therapy emphasize aseptic processing needs in compact spaces. Active HEPA‑purged pass‑throughs (featuring interlocks and timed purging cycles) are increasingly popular, as they merge containment, hygiene, and compact form all in one.

GMP regulations and USP <797>/<800> guidelines also recommend minimizing room traffic and ensuring proper air handling between zones—pass‑through windows fit these goals perfectly.

Clean Room Devices: Smart, Modular, Cleanroom-Compliant

Clean Room Devices manufactures both manual (CRD315/325/335) and fully automatic electric pass‑through windows. These units are:

- Fully modular and install quickly in standardized wall panels.

- Designed for pharmaceutical cleanrooms, lab suites, compounding pharmacies, and surgical instrument rooms

- Available in configurations ranging from simple flush-mounted manual windows to conveyor-style automated units—offering flexibility in workflow design.

Bringing It All Together: Optimizing Your Cleanroom

For pharmaceutical cleanrooms, pass‑through windows are more than convenient—they’re a strategic tool for maintaining sterility, safeguarding batch integrity, and improving operational ROI. Their design and functionality directly support GMP compliance, personnel safety, and space optimization.

If your facility is redesigning or upgrading, consider evaluating both manual and HEPA‑filtered automated pass‑throughs. Clean Room Devices offers expert guidance and modular solutions that fit diverse pharmaceutical manufacturing contexts. Send samples or plans, and CRD can recommend tailored configurations for your cleanroom.

Ready to Improve Your Pharmaceutical Cleanroom Workflow?

Explore Clean Room Devices’ cleanroom-compatible pass‑through windows and request a consultation to discover how to enhance contamination control, efficiency, and pressure stability in your pharmaceutical cleanroom environment.