Ergonomics in Manufacturing Industries: Reducing RSI Risk in Medical Device Assembly

Ergonomics in manufacturing industries has evolved into a critical element of workplace safety and productivity—especially in cleanroom settings where precision and repeatability are essential. In medical device manufacturing, repetitive hand movements like tubing insertion and fitting assembly can lead to repetitive strain injury (RSI), which silently erodes workforce health and operational efficiency.

The Impact of Repetitive Strain Injury—and How Guidelines Address It

Repetitive strain injury (RSI) is a leading cause of musculoskeletal disorders in manufacturing industries, especially in cleanroom settings. Repeating the same motion—such as inserting fittings into tubing hundreds or thousands of times per shift—can gradually damage muscles, tendons, and nerves. Over time, this leads to:

- Chronic pain and reduced dexterity

- Lower output and quality

- Increased absenteeism or turnover

- Risk of workers’ compensation claims

In highly regulated environments like medical device manufacturing, these injuries don’t just affect workers—they can impact product consistency and lead to deviations from quality standards like ISO 13485, which governs risk-based process control.

While OSHA doesn’t mandate a specific ergonomics rule, it offers clear recommendations to minimize workplace injury. These include reducing repetitive motions, limiting force, using ergonomic tools, and training employees to recognize early RSI symptoms. Similarly, ISO 13485 encourages manufacturers to implement safeguards that protect both operator health and product integrity.

Together, these standards reinforce a common principle: ergonomics in manufacturing industries isn’t just a safety measure—it’s a strategic necessity, especially in cleanroom workflows where precision, hygiene, and consistency are non-negotiable.

Why Ergonomics Is Different in Cleanrooms

Not all ergonomic challenges are created equal. Cleanroom environments introduce additional demands:

- Surfaces must be non-shedding and easy to sanitize

- Equipment must maintain ISO 7 or ISO 8 classification

- Tools need to minimize motion without generating contaminants

- Workers operate in gowned, gloved conditions, increasing strain

That’s where ergonomics in manufacturing industries must be tailored specifically for cleanroom applications—and where Clean Room Devices excels.

How Clean Room Devices Designs for Ergonomics and Cleanroom Safety

Clean Room Devices (CRD) builds tools that reduce RSI while meeting cleanroom standards for sterility, low particulation, and repeatability. Their devices are engineered to reduce hand force, maintain neutral posture, and increase consistency.

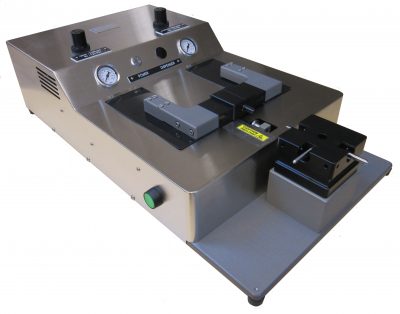

CRD600 Electro-Pneumatic Fitting Inserter

This high-throughput system automates fitting insertions using smart relay control and air pressure. It eliminates manual force, reducing operator fatigue and RSI risk—ideal for medical device manufacturing lines requiring speed and consistency.

CRD100 Electro‑Pneumatic Tubing Cutter

This is a semi-automatic cutter with an electric foot pedal, built for speed and ease of use. Because operators don’t have to apply cutting force, it helps avoid wrist torque and fatigue.

CRD430 Heavy-Duty Manual Inserter

For larger or stiff rubber tubing, the CRD430 provides powerful mechanical leverage in a manual format. It reduces physical strain while maintaining cleanroom compatibility.

CRD201 Time‑Delay Tubing Expander with Foot Pedal

This expander gently stretches the tubing before insertion, giving fittings room to slide on with less force. Because the operator only activates it via a foot pedal, the hands remain relaxed and free of repetitive strain—or wrist torque.

The Business Case for Better Ergonomics

Improving ergonomics in manufacturing industries doesn’t just benefit workers—it supports every level of business performance. CRD tools help:

- Improve fitting consistency

- Reduce rework and errors

- Minimize RSI-related time off

- Boost operator satisfaction

- Support audit and compliance readiness

In medical device manufacturing, where every part must meet strict quality control and traceability standards, ergonomics becomes part of the quality assurance process.

5 Steps to Reduce RSI Risk in Cleanroom Assembly

Cleanroom supervisors and EHS managers can start improving conditions today with these steps:

- Identify high-strain tasks like tubing insertion or cutting

- Assess motion frequency and applied force

- Trial ergonomic alternatives (like the CRD410 or CRD400)

- Train staff on proper posture and tool use

- Collect feedback and monitor RSI incidents over time

These changes can have measurable impact—both in workforce wellness and operational output.

Cleanroom Ergonomics That Work

Ergonomics in manufacturing industries is more than a safety checkbox—it’s an essential part of maintaining cleanroom integrity, supporting regulatory compliance, and protecting the well-being of those who build life-saving devices.Clean Room Devices provides solutions that directly address RSI in cleanroom tubing assembly. By integrating ergonomic design with cleanroom compatibility, CRD helps manufacturers reduce risk, increase consistency, and safeguard their most valuable asset: their people.