Electric Tube Cutters: Types & Uses for 2024

As industries continue to evolve, particularly in fields like medical device manufacturing, biomedicine, and pharmaceuticals, precision equipment such as electric tube cutters plays a critical role. Clean Room Devices is a top name in the industry.

We offer a variety of electric tube cutters that are precise and clean. These cutters are perfect for industries where controlling contamination is very important. These cutters are indispensable in environments such as cleanrooms, laboratories, and medical device manufacturing facilities.

In 2024, the demand for medical tube cutters and medical tubing cutters has seen a significant rise, reflecting the industry’s shift towards automation and precision in cutting medical tubing, where accuracy and cleanliness are crucial for maintaining the integrity of medical devices and other sensitive equipment.

The Importance of Electric Tube Cutters

Electric tube cutters excel in providing accurate, clean cuts, ensuring that each piece of tubing meets exact specifications. In medical and pharmaceutical applications, the cleanliness and precision of cuts directly affect product quality and safety.

For example, medical tubing in catheters or drug delivery systems must be clean and smooth. Any debris or rough edges could harm how the device works. Clean Room Devices designs its cutters to not only meet but exceed industry standards, making them an essential tool in ensuring compliance with both operational and regulatory requirements.

Key Features of Top Electric Tube Cutters

When choosing electric or medical tubing cutters, several features make these tools invaluable for high-stakes industries:

- Precision and Speed: Clean Room Devices’ cutters are designed to deliver quick, accurate cuts, ensuring that industry standards for cleanroom manufacturing are met.

- Clean Room Compatibility: Constructed from materials that prevent contamination, these cutters are tailored for cleanroom settings where maintaining a sterile environment is essential.

- Versatility: These cutters can handle various materials, from soft medical-grade plastics to industrial-grade tubing, accommodating the diverse needs of medical, pharmaceutical, and semiconductor manufacturing.

Exploring Clean Room Devices’ Electric Tube Cutters

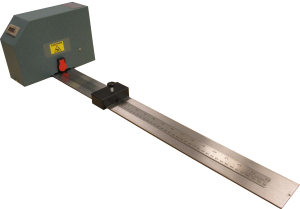

CRD100 Medical Tubing Cutter

The CRD100 Medical Tubing Cutter is perfect for cutting tubing sizes ranging from 1/16″ to 1/2″ OD. Designed specifically for cleanroom environments, this device ensures contaminant-free operations. It is especially useful in the medical tubing cutter market, where precise cuts are crucial for the production of medical devices such as catheters, IV lines, and surgical tubing.

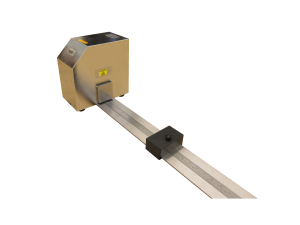

Large Electro-Pneumatic Cutters (CRD180 Series)

For larger tubing, the CRD180 Series can handle diameters from 1/2″ to 1-1/2″ OD. These cutters are designed for high-volume environments and are suitable for industries like pharmaceuticals and heavy machinery manufacturing, where larger diameter tubes are common. Their ability to make clean, precise cuts ensures that medical tube cutters are compliant with strict regulations, especially when dealing with critical applications like oxygen delivery systems and other life-saving equipment.

CRD190 60° V-Notch Medical Tube Cutter

This specialized cutter is ideal for medical tubing where a V-notch is required. The CRD190 is highly regarded in the medical device industry, where notched tubing is often necessary for the assembly of intricate devices, such as those used in minimally invasive surgeries or diagnostic tools.

CRD170 Multi-Angle Tubing Cutter

The CRD170 Multi-Angle Tubing Cutter offers the flexibility to cut tubing at various angles, ranging from 15° to 90°. This makes it ideal for applications in medical device design, aerospace, and electronics where precision angle cuts are essential for the final product.

Industry Applications of Electric Tube and Medical Tubing Cutters

Medical Device Manufacturing: Medical tubing is an essential component in devices like catheters, IV lines, and drug delivery systems. Clean and precise cuts are critical to ensure device functionality and patient safety. Medical tubing cutters help maintain the integrity of these products by ensuring that tubing is cut to exact specifications without contamination or rough edges.

Pharmaceutical Production: Electric tube cutters are crucial in ensuring accurate cutting of tubes used in drug delivery systems, where even the smallest deviation can impact dosage accuracy or lead to contamination risks. The precision offered by Clean Room Devices’ cutters helps ensure that drug delivery systems function flawlessly.

Semiconductor Manufacturing: In the production of semiconductors, precise and clean cuts are essential to protect the integrity of circuits and chips. Tubing used in cleanroom environments for semiconductor manufacturing must meet strict standards for cleanliness and accuracy, which makes electric tube cutters a valuable asset.

Laboratory Research: Researchers rely on clean, precise cuts in tubing for preparing specimens, setting up experiments, and performing tests. Electric and medical tubing cutters are indispensable tools in laboratories worldwide, enabling researchers to work efficiently without contamination risks.

Advancements in Electric and Medical Tube Cutting for 2024

As we move through 2024, advancements in electric tube cutters and medical tubing cutters are centered on automation, precision, and user-friendly interfaces. Anticipated innovations include:

- Automated Feeding Systems: Increased automation is expected to improve efficiency, allowing for quicker and more precise cuts with minimal manual intervention. These systems will benefit high-volume manufacturers of medical devices, where speed and accuracy are critical.

- Advanced Digital Controls: These controls will enhance precision and provide users with real-time feedback on cutting operations, helping to prevent errors and prolong machine lifespan. Such advancements will be particularly beneficial in medical applications where even a slight variance in tubing length can affect device performance.

- Sustainability Initiatives: With a growing focus on sustainability, manufacturers are looking to reduce energy consumption and waste in tube cutting processes. Newer models are expected to be more energy-efficient and made from recyclable materials, reflecting the industry’s push towards greener manufacturing.

Conclusion

In the high-stakes world of medical device manufacturing, pharmaceuticals, and other precision-driven industries, the importance of electric and medical tubing cutters cannot be overstated. As we move through 2024, Clean Room Devices stays at the forefront. We provide advanced solutions that meet the tough needs of modern manufacturing.

Whether it’s precise cuts for medical tubing or cleanroom-compatible devices, these electric tube cutters continue to set the standard for innovation, precision, and contamination control. As automation and sustainability become more critical, Clean Room Devices is poised to deliver even greater efficiency and precision for industries that rely on flawless tubing cuts.