In the medical and pharmaceutical industries, precision and efficiency are paramount. One crucial component that supports these industries is the tubing expander. At Cleanroom Devices, we offer a wide range of medical expanders designed to meet the highest standards of quality and reliability. In this comprehensive guide, we’ll explore the various tubing expanders available at Cleanroom Devices, highlighting their features, benefits, and applications.

Understanding Tubing Expanders

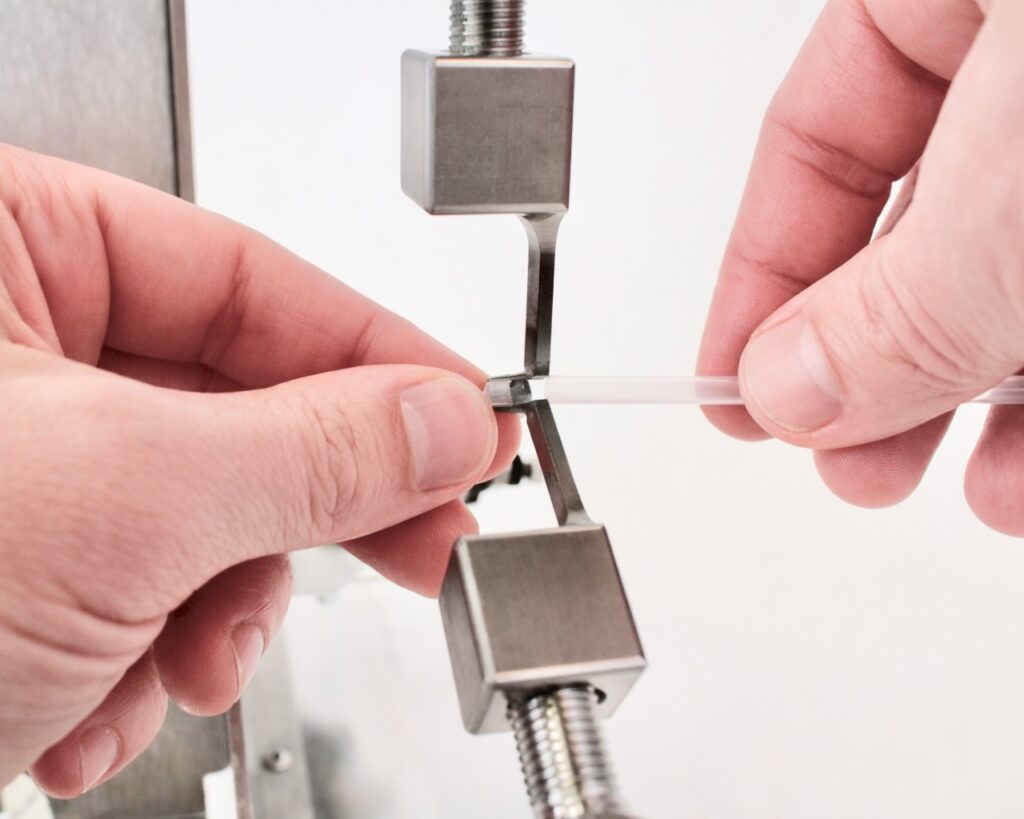

A tubing expander is a tube device used to enlarge the diameter of the tube, ensuring a secure and leak-proof fit when connecting tubes to fittings or other tubes. This process is essential in medical applications where precise connections are critical to maintaining sterile environments and preventing contamination.

The tubing expander works by inserting it into the tube and then expanding to stretch it to the desired diameter. This ensures a tight fit, which is crucial in medical and pharmaceutical settings where even a slight leak can lead to contamination and serious health risks.

Pneumatic Expanders

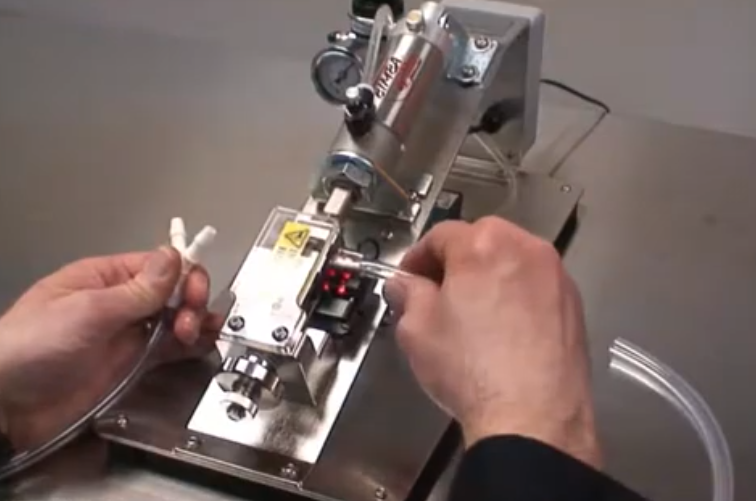

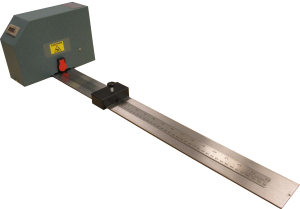

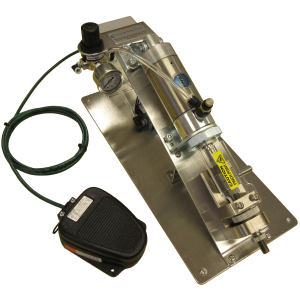

CRD200SS Tubing Expander with Stainless Steel Base

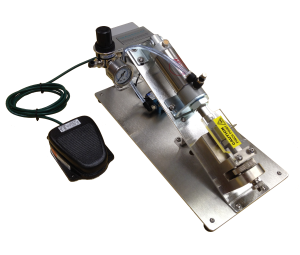

The CRD200SS Tubing Expander is a pneumatic expander featuring a robust stainless steel base. This model is designed for durability and reliability, making it ideal for cleanroom environments where consistent performance is crucial.

The stainless steel base ensures longevity and resists corrosion, maintaining hygiene and sterility. The pneumatic operation allows for precise control, essential for medical and pharmaceutical connections. The CRD200SS is easy to use and maintain, with a straightforward design that ensures minimal downtime and maximum productivity.

The stainless steel base is particularly beneficial in cleanroom environments, as it is resistant to the harsh chemicals and cleaning agents used to maintain sterility. This resistance ensures that the expander remains in top condition even after repeated cleaning cycles, providing reliable performance over time. The ease of use and maintenance also means that the CRD200SS can be quickly integrated into existing workflows, reducing the time needed for staff training and ensuring that production can continue without interruption.

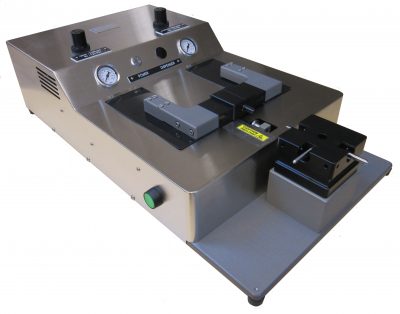

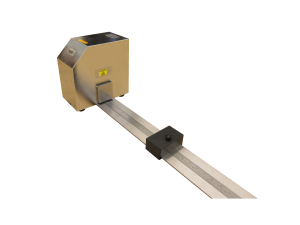

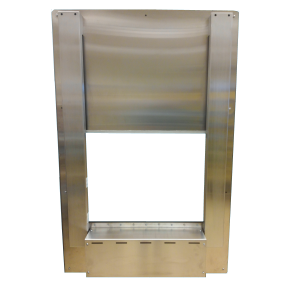

CRD220SS Heavy-Duty Tubing Expander

For more demanding applications, the CRD220SS Heavy-Duty Tubing Expander offers superior performance. This model is designed to handle larger and more rigorous usage, making it perfect for high-volume production environments. The heavy-duty construction ensures long-lasting performance, even under the most demanding conditions. The stainless steel base provides durability and resistance to corrosion, while the pneumatic operation allows for precise control and consistent results.

The CRD220SS is ideal for high-volume medical tubing production and industrial applications where robust equipment is essential. Its heavy-duty design means it can withstand the rigors of continuous use, making it a reliable choice for large-scale operations. The precise control offered by the pneumatic operation ensures that every expansion is uniform and consistent, reducing the risk of leaks and ensuring the integrity of the connections.

Time-Delay Electro-Pneumatic Expanders

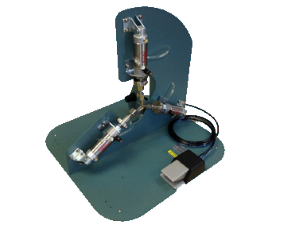

The CRD201 Time Delay Tubing Expander introduces an advanced time-delay feature, allowing for controlled expansion. With a foot pedal for hands-free operation, this expander enhances productivity and precision in cleanroom environments. The time-delay function ensures that it is expanded at the optimal rate, reducing the risk of damage and ensuring a secure fit.

The foot pedal operation allows for hands-free use, which is particularly beneficial in cleanroom environments where maintaining sterility is crucial. By eliminating the need for manual operation, the foot pedal reduces the risk of contamination and ensures that the user’s hands remain free for other tasks. The durable construction of the CRD201 ensures reliability, making it an ideal choice for medical device manufacturing and pharmaceutical tubing assembly.

The time-delay feature is especially useful in applications where precise control is essential. By allowing the user to set the expansion rate, the CRD201 ensures that it is expanded evenly and without stress, reducing the risk of damage and ensuring a tight, leak-proof fit. This precision makes the CRD201 an excellent choice for applications where the highest standards of quality are required.

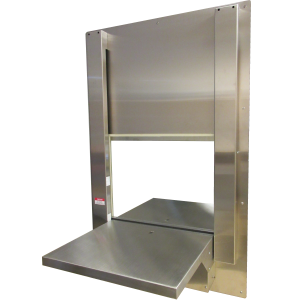

For applications requiring both heavy-duty performance and precise control, the CRD221 Heavy-Duty Time Delay Tubing Expander is the perfect solution. This model combines the robustness of heavy-duty expanders with the precision of time-delay controls. Its foot pedal operation allows for hands-free use, making it suitable for high-volume medical and pharmaceutical production and industrial applications.

The CRD221 is designed to handle the most demanding applications, with a heavy-duty construction that ensures long-lasting performance. The time-delay feature allows for precise control, ensuring that it is expanded evenly and without damage. The foot pedal operation enhances productivity by allowing for hands-free use, reducing the risk of contamination and ensuring that the user’s hands remain free for other tasks.

The heavy-duty design of the CRD221 makes it ideal for large-scale operations where robust equipment is essential. Its precise control and reliable performance make it a valuable addition to any production environment, ensuring that the connections are secure and leak-proof.

3-Jaw and 4-Jaw Expanders

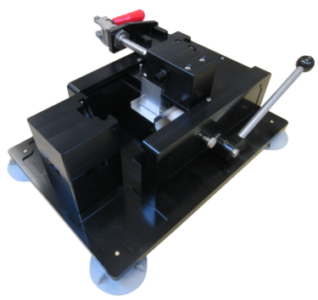

CRD500 3 Jaw Tubing Expander

The CRD500 3 Jaw Tubing Expander offers reliable and precise expansion using a three-jaw mechanism. This model is ideal for applications where uniform expansion is critical. The three-jaw mechanism ensures that it is expanded evenly, providing a tight, secure fit that is essential in medical and pharmaceutical applications.

The robust construction of the CRD500 ensures reliability and ease of operation, making it suitable for medical device manufacturing and pharmaceutical tubing connections. Its straightforward design makes it easy to use and maintain, reducing downtime and ensuring that production can continue without interruption.

The three-jaw mechanism of the CRD500 provides a uniform expansion, which is crucial in applications where precision is essential. By expanding the tubing evenly, the CRD500 ensures that the connections are secure and leak-proof, reducing the risk of contamination and ensuring the integrity of the connections.

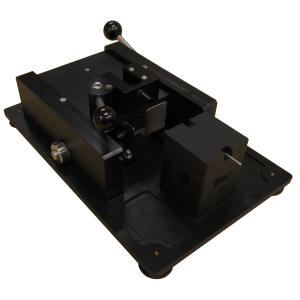

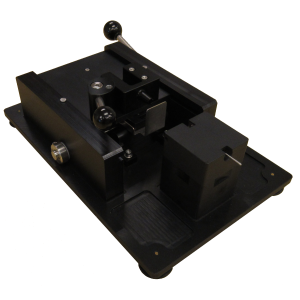

CRD520 4 Jaw Tubing Expander

For applications requiring even greater precision, the CRD520 4 Jaw Tubing Expander provides four-point expansion, ensuring the most uniform and secure tubing connections. The four-jaw mechanism ensures that it is expanded evenly from all sides, providing a tight, secure fit that is essential in high-precision applications.

The durable construction of the CRD520 is designed for cleanroom use, offering easy operation and maintenance. Its robust design ensures reliability and long-lasting performance, making it suitable for high-precision medical and pharmaceutical applications and industrial tubing assembly.

The four-jaw mechanism of the CRD520 provides a uniform expansion that is crucial in applications where the highest standards of quality are required. By expanding the tubing evenly from all sides, the CRD520 ensures that the connections are secure and leak-proof, reducing the risk of contamination and ensuring the integrity of the connections.

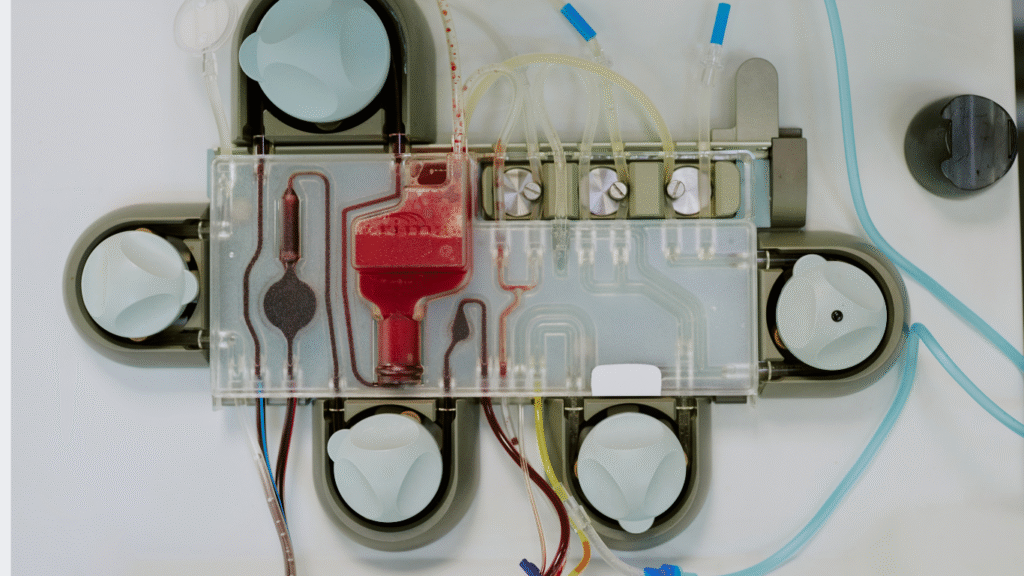

Heated Electro-Pneumatic Expanders

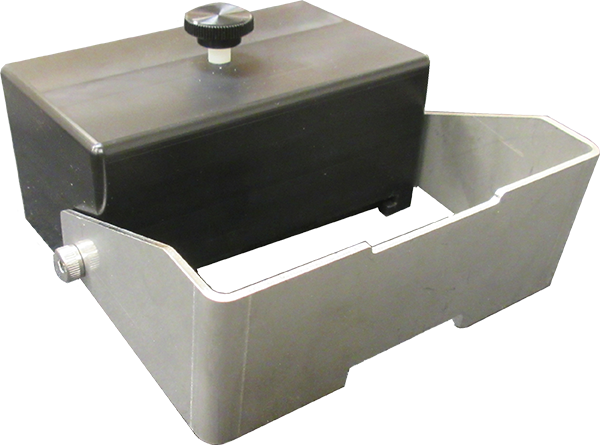

CRD216SS Time Delay Heated Tubing Expander

The CRD216SS Time Delay Heated Tubing Expander combines the benefits of time-delay control with the added advantage of heating. This feature ensures that tubing is more pliable during expansion, reducing the risk of damage and improving the quality of the connection. The heated expansion process makes it more flexible, allowing for a tighter, more secure fit.

The stainless steel construction of the CRD216SS ensures durability, making it suitable for medical tubing requiring heated expansion and pharmaceutical applications demanding precise and reliable connections. The time-delay control allows for precise expansion, ensuring that it is expanded evenly and without damage.

The heated expansion feature of the CRD216SS is particularly beneficial in applications where the highest standards of quality are required. By making the tubing more pliable, the heated expansion process reduces the risk of damage and ensures a tight, secure fit. This precision makes the CRD216SS an excellent choice for applications where the highest standards of quality are required.

Why Choose Cleanroom Devices for Tubing Expanders?

At Cleanroom Devices, we understand the critical role that tubing expanders play in medical and pharmaceutical industries. Our products are designed to meet the highest standards of quality and performance. Our expanders are built with high-quality materials, ensuring long-lasting performance even in demanding environments.

The time-delay and multi-jaw expanders provide precise control, ensuring uniform and reliable expansions. Designed with user-friendliness in mind, our expanders are easy to operate and maintain, minimizing downtime and enhancing productivity. With a wide range of models, we offer tubing expanders suitable for various applications, from small-scale medical device manufacturing to large-scale pharmaceutical production.

Our commitment to quality and customer satisfaction ensures that our expanders meet the highest standards of performance and reliability. We understand the unique challenges of the medical and pharmaceutical industries, and our products are designed to meet these challenges head-on. Whether you need a pneumatic expander for cleanroom use, a time-delay electro-pneumatic expander for precise control, a 3-jaw or 4-jaw expander for uniform expansion, or a heated electro-pneumatic expander for enhanced pliability, we have the perfect solution to meet your needs.

Conclusion

Investing in a high-quality tubing expander from Cleanroom Devices is a smart choice for any medical or pharmaceutical operation. Whether you need a pneumatic expander, a time-delay electro-pneumatic expander, a 3-jaw or 4-jaw expander, or a heated electro-pneumatic expander, we have the perfect solution to meet your needs. Explore our product range and experience the difference that precision and quality can make in your cleanroom operations.